A few Benchmarks of our Journey

Inspiration

In order to present something inspiring you first need to have inspiration yourself. It was the enthusiasm for sound and electronics of two young students, Mr Ilpo Martikainen and Mr Topi Partanen, some 40 years ago, which later made them become founders of Genelec. They did not know it at that time, but such foundation was needed before ideas and products could become visible.

The same can be seen in the work of many of our friends: the desire to reach their dream, the motivation to achieve something remarkable, the willingness to put their heart into their work.

Before it can come out, one needs to have that internal flame.

No wonder one of the values of Genelec is Enthusiasm. This is something we share with our customers.

Roots in Broadcast

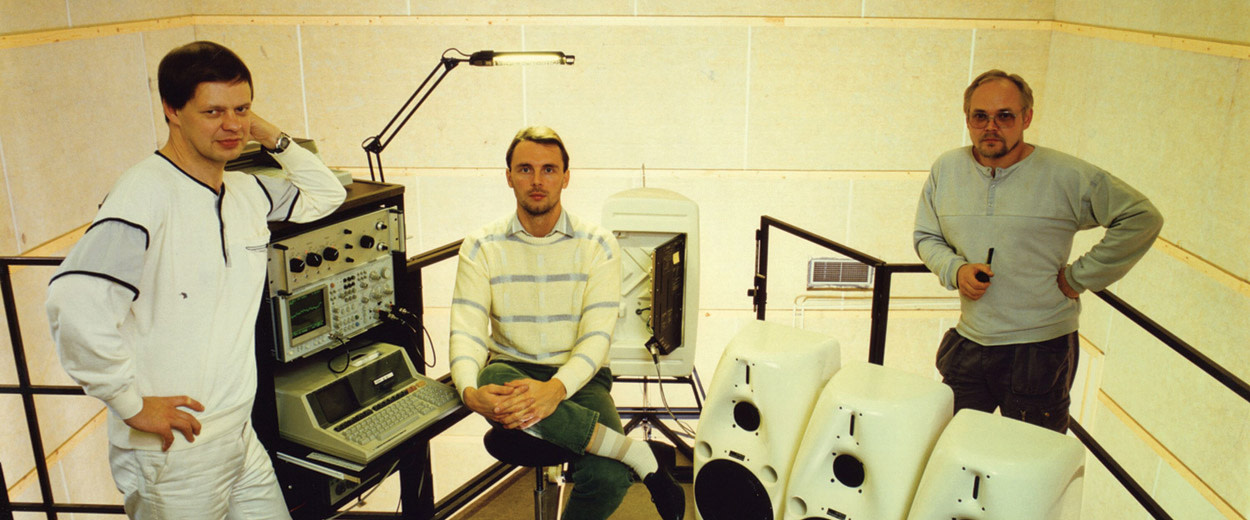

In 1976 YLE, the Finnish Broadcasting Company was building a new radio house in Pasila, Helsinki. Mr. Juhani Borenius, who worked as an acoustician for YLE, asked his friends at a post-graduate acoustics seminar if they could make an active monitoring loudspeaker. First Ilpo Martikainen and Topi Partanen needed Borenius to precise what he was looking for, and two weeks later they produced the first sample. The prototype was far from perfect but promising enough to raise serious interest. In 1978, after two years of serious research and development, Genelec Oy was founded and the first active monitoring loudspeaker, the S30, was ready.

For its time the monitor was very advanced both electronically and acoustically. The customer specification was advanced as well. In addition to normal requirements to be measured in an anechoic chamber, these specifications detailed acoustic performance also in a control room.

Together with the requirement for consistent performance, high reliability, easy serviceablity and guarantee for extended spare part supply, this made a challenging start to match the most demanding customer needs of the time. Meeting those specifications required lots of engineering, measurements and testing. Precision tone controls, driver unit protection circuitry, advanced amplifier topologies – all of which have been part of our monitoring loudspeaker design ever since – were developed in 1978. A proprietary HF ribbon driver was developed as well.

This brings us to one of Genelec's values: Belief. We believe in our own ideas, instead of copying others, enabling us to contribute to something unique in the industry. This belief has been rewarded with an uncomparable trust among our customers, for over 35 years in broadcasting and expanding all over the world and into new segments and applications of high precision sound reproduction.

Sound Reinforcement

At its best, sound reinforcement was half of the business of Genelec. The company installed many drama theaters in Finland (among others the National Theatre, City Theatres of Rovaniemi and Kuopio, etc.), the congress hall of the new Cardiologic Hospital in Moscow, the Moscow Circus and even two recording vans for YLE. The last contract job was Tampere Hall and the last reinforcement system supplied went to the Royal Opera in Madrid.

Genelec wanted to become known as a monitor manufacturer above all, and so the decision was taken in 1989 to depart from sound contracting. It became clear that the decision was the right one. But the years spent in contracting taught many valuable lessons – among other things knowing what the life of a contractor is. It is a profession of its own. What could have taught better how to listen to the needs of contractors – whether for commercial installations or for high class residential installations for home entertainment? The basis of the best-in-class loudspeaker systems is there for these expanding applications.

Respect is also an important value at Genelec. Respect includes our relation and attitude to customers, fellow employees, partners, competitors and environment.

Expanded Offering

The first ten years of Genelec were basically a struggle to stay alive. By 1985 Genelec was producing 12 monitor models. Genelec's press release that year tells that there was a rumour going around at the 77th AES convention in Hamburg: that the purpose of the event was to show the complete Genelec active monitor family.

Right after the decision to concentrate on monitoring loudspeakers an opportunity opened to design a very loud and clean Control Room Monitor. Soon after its introduction in London in 1989, the 1035A became very popular in major Japanese studios and paved way for new types of monitors combining very low distortion and coloration with high output - an unprecedented combination prior to that.

The 1990's were a time for establishing a position as leading manufacturer of active monitoring speakers. New, smaller products were developed, the brightest pearl perhaps being the 1031A in 1991. Nowadays, regarded as the most important product of the 90's in the pro audio business, it is also known as the mother of all modern two-way active monitors.

Our current offering is the most complete on the market place: from the very compact 8010 to the massive 1036A, for any location of any size. With its reputation for excellence and uniquely extensive offering Genelec has also been the benchmark and target for many competing offerings. At Genelec we regard this as a compliment. Our later product releases show that our ability to surprise positively again and again with new proprietary technologies and designs has only been inspired by the attention to details.

This is easy when one of the values of the company is Integrity. We share facts, and our specifications stand the most advanced measurements. The more our customers and partners know the better for us also. We are here for sustainable and mutual success.

Directivity Control

In 1983 Genelec made its first drafts of the 1022A which came into production in 1985. This was a radical development from the shape of the 1024A. The aim was to eliminate diffraction by making the cabinet rounded and to control the directivity the drivers were recessed in a carefully formed waveguide. The result was acoustically breathtaking with the typical pressure response falling into a +0.75 dB window.

This was the starting point of our proprietary Directivity Control Waveguide™, or DCW™ technology, which has been used ever since in our loudspeaker designs, large and small. In the conventional rectangular enclosures the DCW™ houses the tweeter and the midrange drivers, and in die-cast enclosures the DCW™ is integrated into the enclosure itself. With properly controlled directivity the off-axis response is much flatter than otherwise, which means a wider listening area with the same tonal characteristics as when listening on-axis. At the same time edge diffractions are minimised.

Loud and Clean

In 1988 Genelec put a lot of effort to design the loudest and cleanest control room monitor in the market. The design was started by recording the actual sound pressure level at a drummer's ear, since musicians often want to hear their playing at its natural volume in the control room. A high output low distortion midrange driver, a new 3 kW amplifier, a large DCW™, improved driver thermal protection and amplifier diagnostics had to be developed.

The 1035A was introduced in 1989 and it soon became very popular in both UK and Japan. New woofers appeared in the 1035B revision at the end of 1993. Based on the 1035B, the new flagship 1036A was developed in 1997. Its 19 Hz low frequency cut-off implied the use of a larger enclosure and dual 460 mm (18") woofers.

Aluminium for Heavy Metal

Many people think a good loudspeaker enclosure must be made from wood-based material. That is not the case. The first Genelec die-cast aluminium model was the 1029A, introduced in 1996. The birth of this small miracle was triggered by our Italian and French distributors who saw the need for a smaller product. Die-cast aluminium offered, among stiffness and other benefits, large internal volume in relation to the external enclosure size.

As this technology proved its value, it was natural to continue on this route. Co-operation with Harri Koskinen, one of the most acknowledged industrial designers of our time, lead first to the birth of the 6040A (2001) and then to the launch of the 8000 Series (2004). With the curved and stiff Minimum Diffraction Enclosure™, advanced DCW™, optimised die-cast aluminium structure, high performance reflex port design, new low distortion drivers with sophisticated filtering technique, versatile mounting features and Iso-Pod™ (Isolation Positioner/Decoupler), these products set a new standard in two-way monitors.

At first – and form a distance – some people were mistaken to believe these smoothly curved speakers were made of plastic, as was customary for rounded shapes. But a closer look revealed the true construction. The extremely durable semi-matt finish and acoustically optimised metal grilles allow for intensive handling without damaging the monitor. It is light metal and capable of handling demanding monitoring with minimum distortion!

How Deep is Deep?

When a prototype of the Genelec Laminar Spiral Enclosure™ LSE™ subwoofer was shown to some distributors in 2001, the first reaction was astonishment: "This can turn out to be a total flop or a great success. Basically a subwoofer cannot look like this. On the other hand, if somebody is to redefine the subwoofer, it should be Genelec." Introduced in 2002, this revolutionary and patented subwoofer has proved a great success. The spiral-shaped design yields an extremely rigid enclosure exterior while also forming the subwoofer's integral port. Air flow in and out of the enclosure's interior through the spiral-shaped port is totally unrestricted, which results in an extraordinarily accurate and responsive low-frequency system with very low distortion, matching the quality of the main monitors.

With multichannel audio, professional and consumer systems must be able to reproduce all frequencies from each channel. Main monitors, subwoofers and crossovers should work together to provide a flat response for each channel. To link the subwoofer(s) seamlessly to the main monitoring system, you need a sophisticated bass management and this is what Genelec 6.1 Bass Management System does.

Sound and Form

Industrial design has been in the company agenda for more than 20 years. In an acoustical product its form is part of its performance. Many breakthroughs the audio monitoring field have been created and Genelec is proud to introduce bold initiatives. The aim is consistency – not conservatism. As Genelec stands for long lasting value, the same holds for the form language itself: it is modern but timeless.

When Genelec introduced the 1022A in 1985, it raised many eyebrows. Likewise, when we renewed our two-way range with the 8000 Series in 2004 the change appeared radical for many at the time, as it did not follow the square box conventions. Now the new form with its performance improvements is well accepted – actually it has become a new standard. For us a change is always for a good reason: improved performance.

Designed to Adapt

Actually the requirements issued by the Nordic Broadcasting companies in the late 70's (N12-B) implied an active monitor that should have room response controls. Hence, as explained earlier, the first S30 active monitor had already precision tone controls as well as a bass roll-off control. Since then our room response controls have become ever more refined.

The power of DSP opened new possibilities for controlling the monitoring system. As we had developed the Minimum Diffraction Enclosure™ for the 8000 Series, the logical extension was to continue from this acoustically solid foundation and develop the 8200/7200 Series DSP monitors and subwoofers, introduced in 2006. Extensive experience from hundreds and hundreds of on-site studio measurements had given us good understanding of the challenges of the varying listening environments. The power of the DSP technology and in-house software development were harnessed to bring measurable benefits for the customers. Our GLM™ – Genelec Loudspeaker Manager™ - software brings the entire DSP system together under PC and Mac computer network control. Together with AutoCal™ this system can match every loudspeaker of a stereo or multichannel system, including subwoofers, with unprecedented accuracy to the listening environment in a few minutes. It is the most complete, versatile and easy to use automatic calibration system so far developed. It is like having a Genelec acoustical product specialist on hand any time you wish.

Innovative Technologies

Aiming to manufacture a compact three-way system, the idea to design a new coaxial driver was born in 2008. In order to eliminate fundamental coaxial design problems a unique Minimum Diffraction Coaxial MDC™ driver was developed. This breakthrough design consisted of an integrated midrange-diaphragm-suspension-tweeter. The joint between the midrange diaphragm and the tweeter, as well as with the DCW waveguide was totally smooth and diffraction-free, leading to precise imaging and outstanding sound quality on- and off-axis. Featuring the MDC driver, integrated DSP circuitry and full control via GLM and AutoCal software, the 8260A three-way active monitor was released and set a new standard in three-way systems.

In 2012, Genelec launched the concept of Smart Active Monitor SAM™ systems, a marketing term helping to identify the capability and intelligence of these systems to adapt automatically to their acoustical environments. This includes aligning levels at the listening position, adjusting delays from the signal input to the listening location, and frequency response equalisation for the acoustical room influences. SAM’s can be controlled with digital networking, enabling users to build highly flexible computer controlled networked monitoring systems. The acoustical output of SAM’s can be optimised with software calibration to suit different working styles or client demands.

In the Hall of Fame

End of 1990 Italian Radio RAI were looking for new monitors and a sked if Genelec could design a larger two-way monitor than the existing 1019A. The R&D work started immediately and the basic design decisions were taken after a couple of prototype rounds. The use of the DCW had started in 1984 in the three-way active 1022A and later in 1989 in the large format 1035A. In the 1031A the tweeter DCW was made square and reflex ports were located on its sides to follow the design pattern adopted in larger three-way 1035A, 1034A and 1033A. A new amplifier design featured a separate discrete power amplifier driver module and clever thermal design: power transistors were located on the vertical centre of the rear panel. The amplifier was also modular and the crossover filter was efficiently a plug-in board. Additionally, to prevent any rattles, the amplifier was mounted on rubber shock mounts to isolate it from any vibration caused by the woofer.

In 1991, the high performance 1031A was released and offered a flat response up to 23 kHz, two 120 watts power amplifiers and the ability to reach 120 dB maximum peak output per pair at 1 m with music material. Featuring high, neutral output, wide bandwidth and controlled directivity in a compact, reliable package with extremely tight response tolerances and room response tailoring options, a classic was born. All of these made the 1031A a popular choice with top engineers and producers, studios and broadcasters worldwide. It stayed in production for 15 years, eventually being replaced by the 8050A, part of the 8000 Series monitors.

In 2014, the Genelec 1031A two-way active monitor was inducted in the TECnology Hall of Fame which honours and recognises audio products and innovations that have made a significant contribution to the advancement of audio technology.

Sustainable Designs

Since its founding Genelec design philosophy has been based on sustainability, reliability and environmental values. Conservation of natural resources and efficient use of material and energy in all levels of manufacturing, shipping, and during the product lifetime are essential to Genelec. The low lifecycle carbon footprint products are manufactured under the same roof, in Finland, allowing us to select environmentally efficient solutions.

Genelec factory’s heating is handled with renewable energy. The recycled aluminium used in the manufacturing of the die-cast enclosures saves 95% of energy compared to using virgin aluminium.

Introduced in 2013, the Natural Composite Enclosure (NCE™) of the M Series is made of a material that is best described as fully recyclable injection-mouldable wood composite. Sourced from sustainably managed forests, this natural fibre composite material contains approximately half wood fibres which contribute to excellent enclosure performance. The M Series packaging is made of recyclable cardboard and the shock absorber linings inside the packing are made of recycled paper pulp.

Conserving natural resources extends beyond the use of recyclable natural materials. Products are designed to be durable with a very long life time. Materials are selected so that they can be reused, either in their original purpose or for new types of products. This is the best form of sustainability.

And the story continues...